Gas Membrane Separators

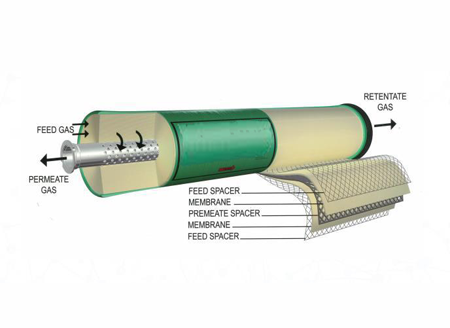

Gas Separation Membrane technology is a well-established process technology that is an alternative to conventional solvent-based process technologies.The Gas Separation Membrane process consists of feeding a gas stream to a membrane unit where the gas is exposed to a semi-permeable membrane designed to separate the desirable gases from other components. A pressure differential is kept across the membrane: a high pressure side (retentate or residue) is separated from a low pressure side (permeate) by such semi-permeable membrane. Thanks to the pressure difference across the membrane, the most permeable components will concentrate in the permeate side.

Two different spiral wound membrane products are available:

- Natural Gas Sweetening Product: designed to separate CO2, H2S and water from a natural gas stream. This product is designed to maximize the CO2 removal capacity by keeping a high hydrocarbon recovery, and to keep stable performances over time. This has been proven in several worldwide installations over recent years;

- Fuel Gas Conditioning Product: designed to separate heavy hydrocarbons (Ethanes+) and H2S from a natural gas stream. This product is designed to maximize the high hydrocarbon removal (selectivity) over methane and to keep stable performances over time. This technology has also been proven under long term operations. This product can also be used to separate Volatile Organic Components (VOC) from VOC-rich streams.

Example of applications for spiral wound membrane modules are reported below.

Natural Gas Sweetening Product

Wellhead Natural Gas Conditioning (onshore/offshore);

Pipeline conditioning;

Acid gas removal / Natural Gas Sweetening;

Enhanced Oil Recovery (EOR);

Biogas /Landfill Gas (LFG) upgrading;

Fuel Gas Conditioning Product

Fuel Gas Conditioning for Gas Engines and Gas Turbines;

Volatile Organic Compounds (VOC) removal;

Syngas applications.